DEHUMIDIFIERS&VENTILATION FANS

We offer a comprehensive range of dehumidifiers and fans for home commercial and industrial use, including advanced technology in various types and capacities. Whatever your needs, we have the right solution for you. Please browse our product range and speak to our experts for more information.

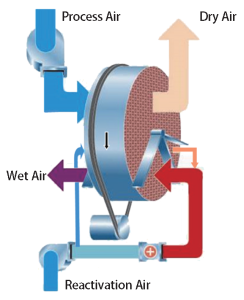

AMD Series Desiccant Dehumidifier

The AMD Series Desiccant Dehumidifier utilizes innovative heat recovery technology to provide energy-efficient, cooler dry air. Ideal for use in cold climates, this large-capacity unit excels in industrial warehouses, manufacturing facilities, and power stations, delivering versatile and reliable humidity control.

Advantages

- Efficient absorption silica gel wheel ·

- Control noise damping and shock absorption · Industrial flange for easy operation ·

- Circuit breaker incorporated to minimize damage at high temperatures for electrical motor; heater and the drive wheel ·

- Leakage protection safeguard for electrical motor; heater and the drive wheel ·

- Unique seal design; Reduces air leakage ·

- Dynamic balance design, ensures stable operation while moving

- Able to operate in a wide range of temperatures from -20˚C + 50˚C heat

- The design is in line with the requirements of IEC protection Class IP44

Product Description

AMD series uses unique heat recovery technology for energy savings and cooler dry air. This large capacity unit is equally at home in an industrial warehouse, large manufacturing facilities or a power station injecting clean dry air into decommissioned turbines. Machines of this calibre have a variety of uses.

The desiccant wheel itself is made of quality silica gel material, which is very good at absorbing water vapour.

Product Data

| Model | AMD-400 | AMD-600 | AMD-800 | AMD-1000 | AMD-1200 | AMD-1500 | AMD-2500 | AMD-3000 |

|---|---|---|---|---|---|---|---|---|

| Dehumidification capacity (@ 20˚C, 60%)Kg/h | 2.2 | 3 | 4.6 | 7.5 | 8.5 | 10 | 15 | 19 |

| Process air flow (m³/h) | 400 | 600 | 850 | 1100 | 1250 | 1550 | 2500 | 3000 |

| Static pressure at disposal(Pa) | 80 | 80 | 250 | 250 | 350 | 350 | 400 | 450 |

| Reactivation air flow(m³/h) | 125 | 200 | 260 | 400 | 450 | 580 | 925 | 1100 |

| Static pressure at disposal(Pa) | 50 | 80 | 110 | 200 | 210 | 210 | 200 | 300 |

| Power(Kw) | 1.89 | 5.1 | 10 | 11 | 13 | 15 | 24 | 27 |

| Operating temperature range | -20℃~50℃ | -20℃~50℃ | -20℃~50℃ | -20℃~50℃ | -20℃~50℃ | -20℃~50℃ | -20℃~50℃ | -20℃~50℃ |

| Input Power | 220V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Current(A) | 8.6 | 23 | 16 | 18 | 20.5 | 23 | 35 | 42 |

| Process of air intake flange sizes(mm) | 160 | 130 | 200 | 200 | 250 | 250 | 400 | 522*286 |

| Process of air Supply flange sizes(mm) | 100 | 100 | 200 | 200 | 250 | 250 | 450*223 | 400 |

| Reactivation of air intake flange sizes(mm) | 160 | 130 | 150 | 150 | 160 | 160 | 200 | 200 |

| Reactivation of air Supply flange sizes(mm) | 100 | 100 | 150 | 150 | 160 | 160 | 200 | 200 |

| Product Size(mm) | 751*475*503 | 505*420*866 | 875*640*1232 | 875*640*1232 | 880*678*1238 | 880*678*1238 | 1312*856*1300 | 1312*856*1300 |

| Net Weight(Kg) | 60 | 70 | 150 | ·160 | 175 | 180 | 270 | 280 |

Related products

FAQ

- Operating Principle: Desiccant dehumidifiers use moisture-absorbing materials, while conventional dehumidifiers use refrigerants to condense moisture from the air.

- Low-Temperature Performance: Desiccant dehumidifiers are more effective in low-temperature environments, whereas conventional dehumidifiers may struggle or become inefficient.

- Noise Levels: Desiccant dehumidifiers typically operate more quietly compared to conventional dehumidifiers.

- Energy Efficiency: Conventional dehumidifiers are generally more energy-efficient in warm, humid conditions, whereas desiccant dehumidifiers excel in cooler, drier environments.

- Applications: Desiccant dehumidifiers are better suited for specialized environments that require low humidity levels, such as pharmaceuticals, food storage, and archival storage, while conventional dehumidifiers are commonly used in homes and offices.

- Space Size: Measure the area (in square meters or square feet) that needs dehumidification.

- Humidity Levels: Assess the current and desired humidity levels. Higher humidity levels require a dehumidifier with greater capacity.

- Environmental Temperature: Know the temperature of the space, as desiccant dehumidifiers perform well in low temperatures.

- Ventilation: Consider the ventilation of the area. Enclosed spaces often need more efficient dehumidification.

- Usage Frequency: If the dehumidifier will be used continuously, select a durable and efficient model.

- Low-Temperature Environments: Such as basements and cold storage rooms, where they remain effective.

- Industrial and Commercial Use: Including pharmaceutical manufacturing, food processing, and electronics manufacturing, where precise humidity control is crucial.

- Archival Preservation: Libraries, archives, and museums where the protection of artifacts and documents requires stable low-humidity conditions.

- Maritime and Marine Environments: On ships and boats where high humidity can cause mold and corrosion.

- Dry Storage: For grains, seeds, and other agricultural products that require low humidity for preservation.